How to take Zero Waste to Landfill from a concept to an achievable goal.

Zero waste to landfill (ZWL) is an environmentally friendly philosophy that seeks to minimize waste in landfills. South African industrial and commercial players realize the importance of shifting the concept of ZWL into a goal they must achieve. According to the 2018 State of Waste Report, South Africa generated 55 million tonnes of general waste, with only 11% diverted from landfills.

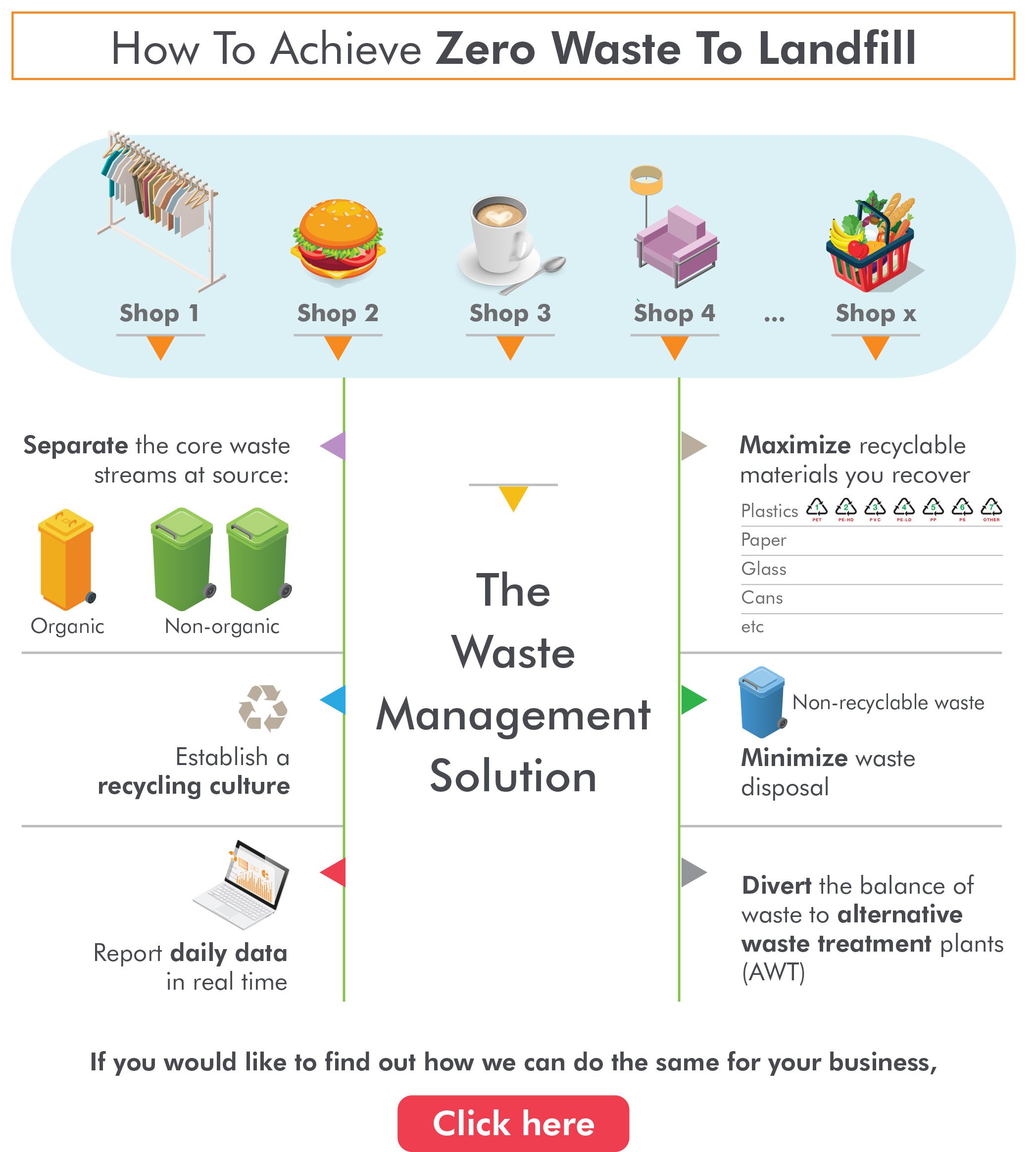

How to achieve ZWL

Waste management starts at the source, where you are. You need a solution that can:

● help you separate the core waste streams at source between organic and non-organic

● establish a recycling culture

● report daily data in real time,

● maximize recyclable materials you recover,

● minimize waste disposal, and

● divert the balance of waste to alternative waste treatment plants (AWT).

Within the recycling industry, there is what everyone knows, and then there is what the experts with experience know. An effective ZWL plan optimizes all the steps in a "waste management hierarchy" then proceeds to optimize, manage, and control the traditionally "difficult to recycle" products.

The Waste Hierarchy is the baseline for Zero Waste to Landfill initiatives; it highlights the solutions for waste before ending up in a landfill. The waste hierarchy depicts solutions to get the most out of waste, namely:

● Prevention

● Reuse

● Recycle

● Recovery

● Disposal

The National Waste Management Strategy (NWMS) aims to utilize waste management hierarchy and circular economy principles to minimize waste by diverting 70 per cent of waste from landfills by 2035 and ultimately leading to zero waste going to landfills.

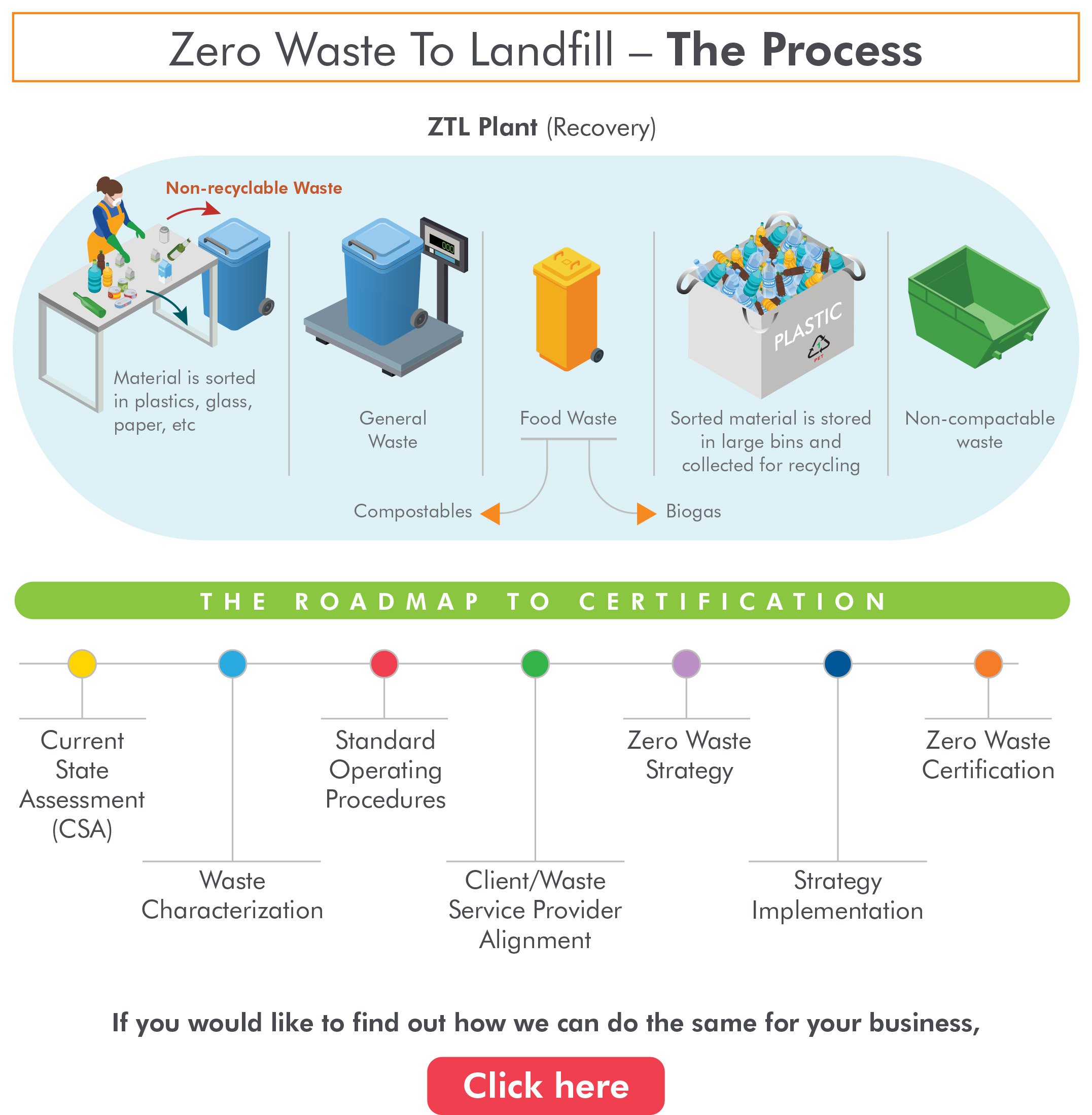

Zero Waste to Landfill - The process Zero Waste to Landfill

Recovery is the principal focus of an effective ZWL plant. Recovery is a waste management process that diverts waste material from the waste stream and turns it into an economic or ecological value product. To achieve this, you must carefully plan a series of activities that need to be engaged and adopted as a road map that can lead you to certification. These are:

1. Current State Assessment (CSA)

2. Waste Characterization

3. Standard Operating Procedures

4. Client/Waste Service Provider Alignment

5. Zero Waste Strategy

6. Strategy Implementation

7. Zero Waste Certification

Why is Zero Waste to Landfill important to your business?

Cities have used landfills as a disposal method, but it isn't a viable long-term solution. Landfills are running out of space, and they have a negative environmental impact. If companies reduce waste, their actions will positively impact the environment.

Businesses can benefit from cost savings due to using materials more effectively and longer. Your business will be able to do more with less and make gains from the economic value of its waste.

Climate change is forcing governments to set regulations and tighten controls, including waste management. Your business needs to stay compliant with the latest legislation. Environmental credentials can also improve a company's brand, especially as consumers become more environmentally aware.

Zero Waste initiatives are a long-term commitment to reduce waste output until the business eventually creates no waste at all. This goal is achievable, but it needs a total re-evaluation of business processes to prevent waste creation.

Minimizing waste isn't a small feat, but with the right partner, it's possible. WastePlan can assist your organization to develop and implement a waste management plan unique to your needs. WastePlan is a specialist waste management company with experience, expertise, tools, and a track record of significantly reducing its clients waste that is sent to landfills.

Did you know that Waste Plan is currently involved with several national and international clients in the retail, food, beverage, packaging, hospitality, and industrial sectors, who are all committed to achieving Zero Waste to Landfill. Some of them are currently in the certification stage.

Over the years, WastePlan has met the unique operational needs of a diverse range of clients across many sectors. It has developed a custom range of systems and procedures to ensure the maintenance of quality and performance standards.

A key differentiator for WastePlan is that its on-site waste management services have an average waste diversion rate of 83 per cent, achieved by over 680 of our clients nationwide in 2021.

Case Study

In August 2021, a leading retail sector company appointed WastePlan as its property portfolio's new waste management service provider. The established corporate objective of the property portfolio owner is to achieve "Zero Waste to Landfill" in its next financial year.

The property portfolio has a gross leasable area of 143,646 m2. The historic landfill diversion ratio for the 12 months ending 31 July 2021 was 38.4%, and the goal was to achieve 100% diversion from landfills within 12 months for the entire portfolio.

Since the commencement of service on 01 August 2021, we have achieved an average waste diversion rate of 75.9% within the first seven months. Included in the average performance rate achieved, three properties currently enjoy a diversion rate above 90%, and we are on course to achieve the clients' goal of 100% diversion.

Key interventions

The following key interventions contributed to the current level of success that the strategy has achieved thus far:

● The property owner has clearly defined contractual performance targets for the Waste Service Provider

● Close and frequent interaction between the property owner as the employer, the Waste Service Provider, and the tenants as waste generators

● The Waste Service Provider has to provide a technology tool that can identify and track each waste stream from each source (Tennant back door) all the way to final destination

● Focus on the reduction of contamination at the source

● Accurate measurement of all waste and recyclables generated

● Optimization of recycling efficiencies

● Provision of optimized equipment to suit treatment processes

● Establishing markets for some products that were historically non-recyclable.

Get a Waste Gap analysis here.

.png)